- Manual Blast Machines

- Euroblast 2 - Manual Blast Machine

- Euroblast 4 - Manual Blast Machine

- Euroblast 6 - Manual Blast Machine

- Euroblast 7 - Manual Blast Machine

- Euroblast 8 - Manual Blast Machine

- Euroblast 9 - Manual Blast Machine

- Euroblast 10 - Manual Blast Machine

- Euroblast Plus - Manual Blast Machine

- Euroblast Specials - Manual Blast Machines

- Automated Blast Machines

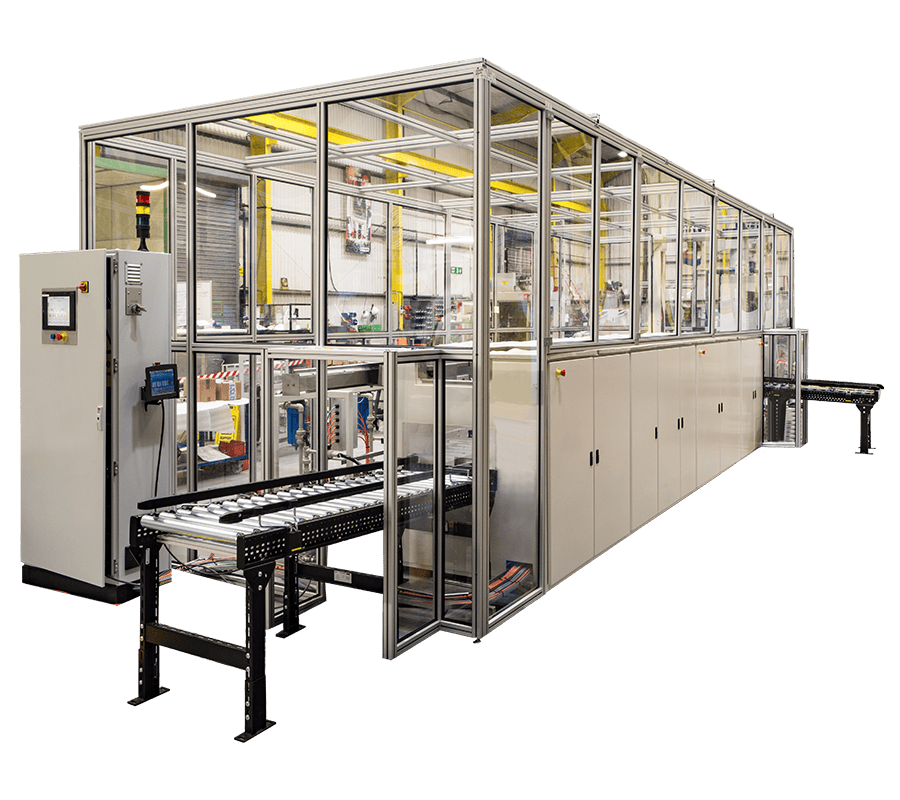

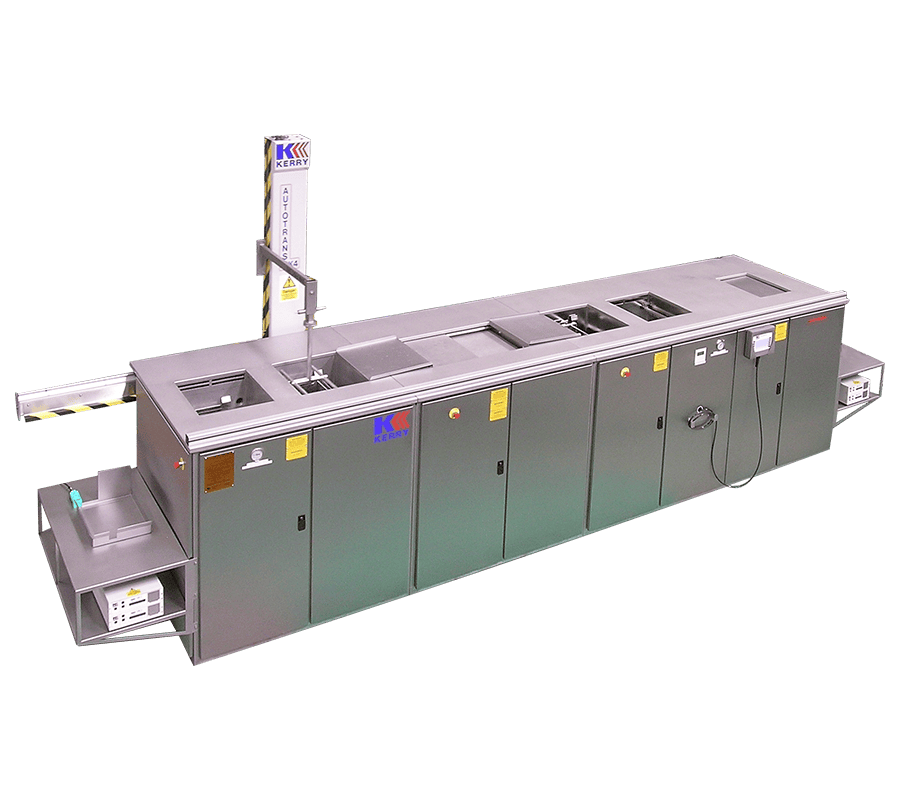

- Automated Ultrasonic Cleaning Systems

- Ultrasonic Baths and Tanks

Details

PLC-based electrical control system, with a touch screen LCD panel showing actual and set point temperatures, pre-set cycle times, and any faults.

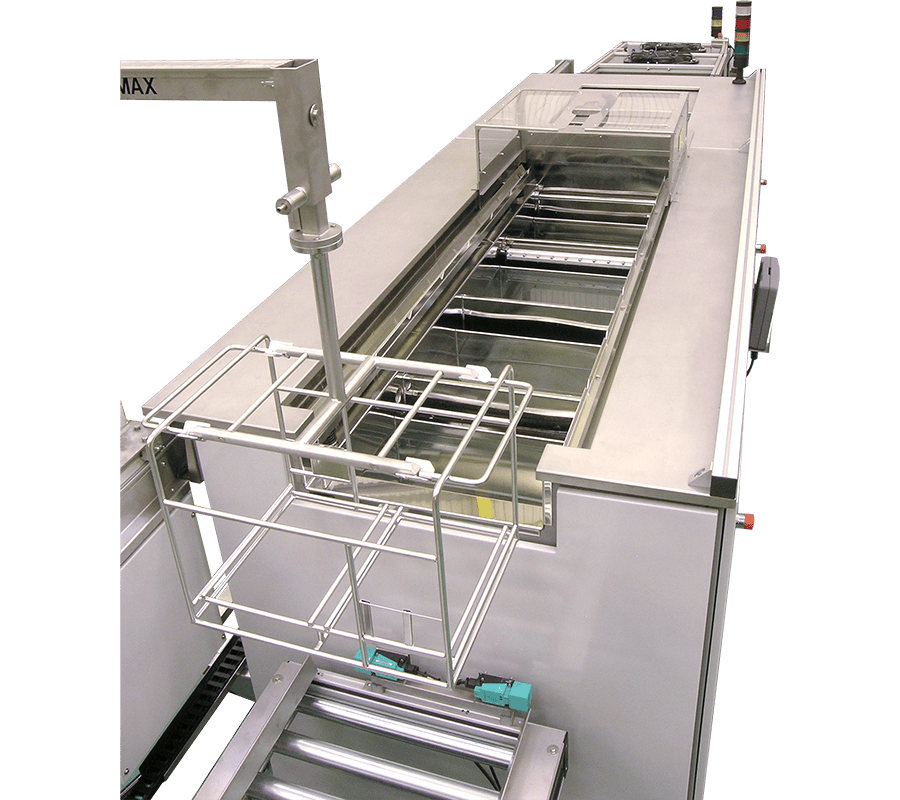

STAGE 1 - ULTRASONIC CLEANING

With heating, spray under immersion, filtration, and optional vertical

agitation.

STAGE 3 - DEIONISED WATER RINSE

With spray under immersion and filtration, optional heating, optional ultrasonics, optional vertical agitation.

STAGE 2 - TOWN WATER RINSE

With spray under immersion, optional ultrasonics, optional vertical agitation.

STAGE 4 - RECIRCULATING WARM AIR DRY

With economy timer; double capacity option.

The Microclean's closed-loop, high purity deionised water rinsing produces organic and ionic cleanliness superior to MIL standard.

Furthermore, due to the Microclean’s modular design, additional stages can be added to meet a variety of process requirements. Alternatively, a 3-stage system (heated ultrasonic clean, rinse, warm air dry) is also available.

Microclean systems may be operated manually, fitted with a lift (3-stage systems), or fitted with Autotrans iDrive automation, where the Microclean's PLC-based control system interfaces with the Autotrans to provide fully automatic operation.

| Model |

Microclean 450 |

|---|---|

| Hardware Type |

Automated |

| Machine Type |

Multi-stage Aqueous Cleaner |

| Overall Dimensions (L x W x H) |

2623 x 1180 x 1202 mm |

| Machine Options |

Pre-clean Module With Oil Separator ,Ultrasonics To Rinse Stages ,Vertical Agitation ,Double Capacity Hot Air Drying ,Autotrans iDrive |

| Finishing Applications |

Precision Cleaning |

Microsolve Benefits

Discover four standout benefits that come from using Guyson’s Kerry Microsolve Ultrasonic Cleaning Systems for your operations.

Benefit 1

Guyson’s Microsolve machines are available in both mono & co-solvent configurations.

Benefit 2

The Microsolve systems have unique solvent retention features as well as effective use of HFE or HFC solvents.

Benefit 3

The Microsolve range operates with low, predictable solvent usage & therefore efficient running costs.

Benefit 4

Guyson’s Microsolve machines are compatible with Autotrans handling systems to increase productivity.

Gallery

360° Product view

Lorem ipsum dolor sit amet consectetur adipiscing elit lobortis, sem quisque duis pretium blandit hac id quam class, facilisis potenti leo senectus aliquam feugiat quis.

Finishing Applications