- Manual Blast Machines

- Euroblast 2 - Manual Blast Machine

- Euroblast 4 - Manual Blast Machine

- Euroblast 6 - Manual Blast Machine

- Euroblast 7 - Manual Blast Machine

- Euroblast 8 - Manual Blast Machine

- Euroblast 9 - Manual Blast Machine

- Euroblast 10 - Manual Blast Machine

- Euroblast Plus - Manual Blast Machine

- Euroblast Specials - Manual Blast Machines

- Automated Blast Machines

- Automated Ultrasonic Cleaning Systems

- Ultrasonic Baths and Tanks

Guyson Internationals extensive portfolio of manual and automatic blasting solutions are renowned throughout the aviation industry. Engineered to AMS standards and tailored to meet the diverse needs of maintenance, repair and overhaul (MRO) applications. This article showcases some key applications in practice, by leading aviation MRO companies’, that have utilised Guyson’s blast finishing equipment to enhance their surface finishing processes.

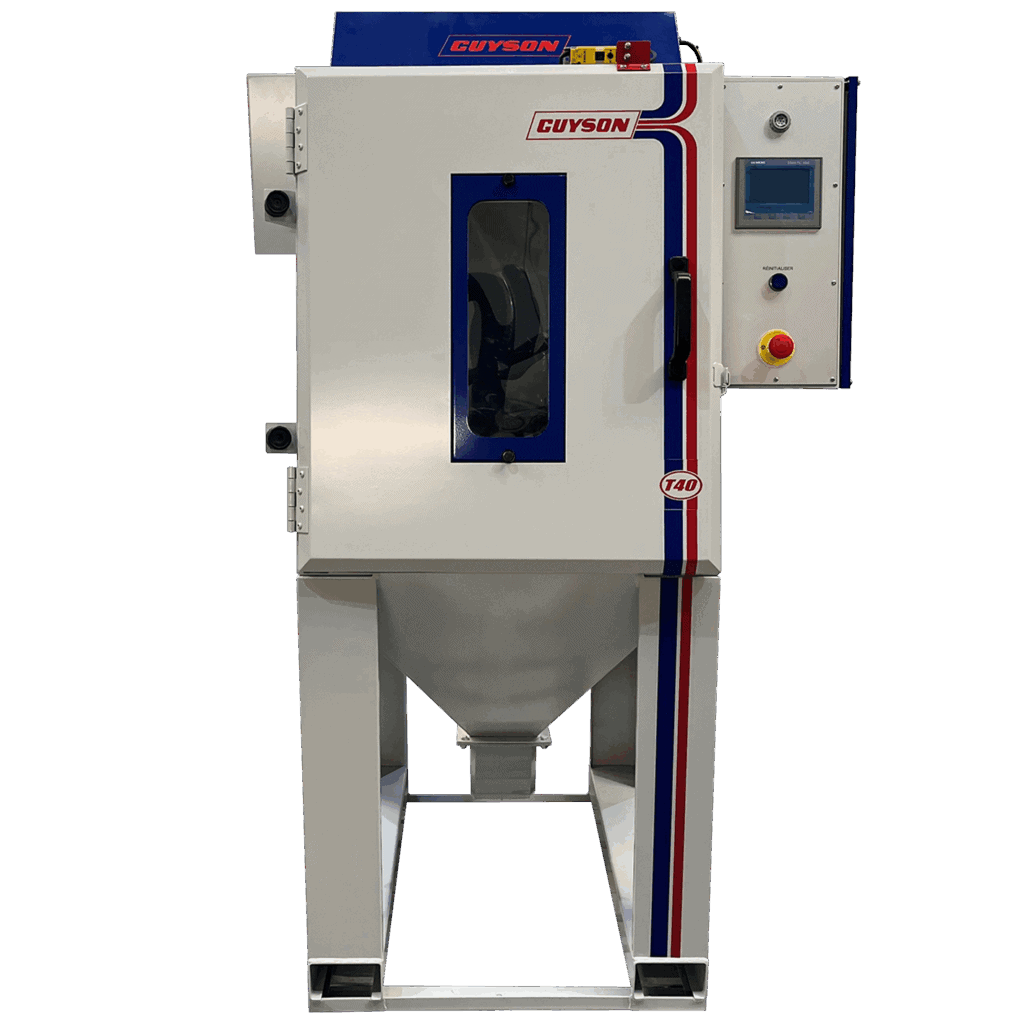

One of the most popular blast solutions Guyson offer into aviation MRO is their Euroblast range of manual blast cabinets. These class leading systems provide a simple yet effective alternative to labour-intensive operations, significantly improving efficiency and output. Available in a variety of sizes to suit different applications, the Euroblast range spans from compact cabinets measuring 660mm x 460mm to specialised, larger cabinets exceeding 2000mm x 2000mm. Common applications undertaken within the Euroblast include paint stripping from landing gear components using plastic blast media, as well as grit blasting aerospace parts made from materials such as aluminium and titanium.

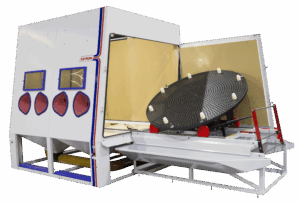

The Euroblast range of cabinets includes numerous customisable features, making them fully configurable for specific application requirements. An example of machine configuration includes the customisation of a highly-efficient Euroblast cabinet. Guyson were approached by a customer with a requirement for the delivery of a uniform etched surface on a range of machined aluminium rings prior to bonding.

The challenging 1.8mtr diameter proved no problem for Guyson offering a Euroblast 2-metre Pressure Feed blast system (2.1m deep x 2.5m wide), incorporating a side loading and forward tilting turntable to accommodate the rings. The tilting action of the turntable allowed the components to be presented in a position that provided improved access to the operator for more accurate blasting and delivered greater ergonomics for operator comfort.

Guyson also supply a wide array of manual & automatic blast machines to leading companies that specialise in the provision of coating technology solutions for turbine blades. Ranging from our standard Formula blast cabinets, through to our robotic blast systems, for the most demanding applications. Guyson equipment plays a vital role in the preparation of turbine blades, to grit etch the surface prior to coating. The process of grit blasting uses abrasive particles to remove old coating, in the case of MRO, creating an etched contaminant-free surface, with increased mechanical bond properties prior to coating. Given the precise nature of this application, automated blast solutions are often preferred, with robotic blast systems offering the optimal level of precision for an industry where precision and repeatability is often not only key but a necessity.

Guyson’s robotic blast machines allow selection of pre-planned programmes containing movement paths and blasting parameters through a user-friendly touchscreen graphical interface, offering unparalleled adaptability and control of critical machine parameters in this high-precision field.

As well as aiding in the preparation of a wide array of vital external components, Guyson’s equipment also plays a key role in the preparation and refurbishment of numerous aircraft interior parts. Two examples include, bead blasting alloy seating to produce a smooth and consistent cosmetic finish, and grit blasting composite window frames, to prepare the surface prior to painting. In both cases, a Guyson Euroblast manual cabinet was the preferred choice due to the systems ease of use, efficient operation, and production output required.

From the 10th-11th February 2025, Guyson International will be attending MRO Middle East & Aircraft Interiors Middle East 2025 at the Dubai World Trade Centre. As the region’s largest maintenance, repair and overhaul (MRO) event, this prestigious gathering offers a unique opportunity for Guyson to connect with aviation businesses across the Middle East. Guyson will be on hand over the two days to discuss how our range of blast cabinets & ultrasonic cleaning machines can meet and exceed the requirements of MRO and original equipment manufacturers (OEM) of all sizes within the aviation industry.

We look forward to the opportunity to demonstrate how Guyson’s innovative blast finishing equipment drives progress in the aviation industry at MRO Middle East & Aircraft Interiors Middle East 2025. If you would like to learn more about how our equipment can enhance your MRO and OEM processes, please contact our Guyson team today.

This project is part-funded by the UK government through the UK Shared Prosperity Fund.

The UK Shared Prosperity Fund provides £2.6 billion of funding for local investment by March 2025. The fund aims to improve pride in place and increase life chances across the UK investing in communities and place, supporting local business, and people and skills. For more information, visit: https://www.gov.uk/government/publications/uk-shared-prosperity-fund-prospectus

Guyson’s ‘Try Before You Buy’ Service

Guyson encourages prospective customers to experience first-hand the benefits that these machine enhancements can make to their operations, by offering free ‘try before you buy’ blast trials at Guyson’s state-of-the-art Blast and Wash demonstration facility. To arrange your free component testing, contact Guyson’s team today.