- Manual Blast Machines

- Euroblast 2 - Manual Blast Machine

- Euroblast 4 - Manual Blast Machine

- Euroblast 6 - Manual Blast Machine

- Euroblast 7 - Manual Blast Machine

- Euroblast 8 - Manual Blast Machine

- Euroblast 9 - Manual Blast Machine

- Euroblast 10 - Manual Blast Machine

- Euroblast Plus - Manual Blast Machine

- Euroblast Specials - Manual Blast Machines

- Automated Blast Machines

- Automated Ultrasonic Cleaning Systems

- Ultrasonic Baths and Tanks

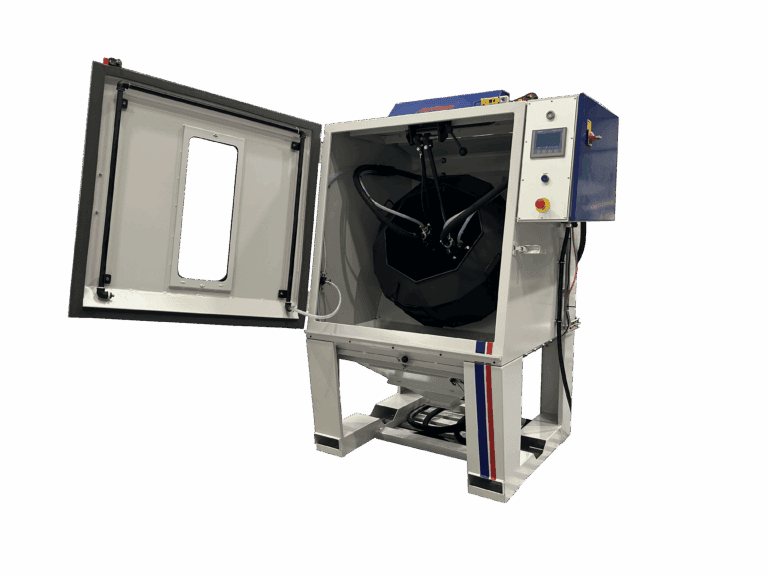

At Guyson International, we take pride in manufacturing a range of automated blast machines including our T50 Tumbleblast, designed to deliver exceptional performance for batch-oriented blast finishing processes. Offering fast cycle times and consistent process quality assurance, this industry-leading equipment provides a highly cost-effective solution.

Widely adopted across a variety of industries, the T50 Tumbleblast is ideally suited for processing small metal components such as screws, bolts, nuts, washers, circlips, and aerospace fasteners. Its specialised design ensures precise and efficient batch deburring, deflashing, machine mark removal, cleaning, surface preparation, and cosmetic finishing, all to the highest standard.

Recently, our team have introduced key enhancements to the T50 Tumbleblast machines, for further functionality and user experience optimisation. These improvements include the integration of a Siemens PLC HMI control panel, an internal door air wash, a heavy-duty basket mounting, a larger opening basket flap, and an external spring-loaded catch for the hopper unload flap.

The advanced HMI screen interface replaces traditional analogue push buttons and switches, offering operators a seamless, user-friendly experience. This highly functional system provides complete control and real-time monitoring of blasting operations. Additionally, it can store multiple blasting recipes, allowing for precise adjustments to various parameters, ensuring optimised and tailored blasting processes for a wide range of applications.

The internal door air wash feature effectively removes excess dust from the front door prior to opening, helping to prevent damage or contamination of components. The newly introduced heavy-duty basket mounting secures the large basket firmly to the back plate, ensuring enhanced reliability and durability, particularly when handling heavier loads.

The incorporation of a larger opening basket flap ensures easier removal of larger components from the basket after blasting. The addition of the external spring-loaded catch enables one-handed operation for releasing the hopper unload flap, replacing the previous two-handed process required for the internal toggle catch, significantly improving convenience and efficiency.

To find out directly how Guyson’s enhanced T50 Tumbleblast can improve your batch-orientated processes, please contact our team today.

Guyson’s ‘Try Before You Buy’ Service

Guyson encourages prospective customers to experience first-hand the benefits that these machine enhancements can make to their operations, by offering free ‘try before you buy’ blast trials at Guyson’s state-of-the-art Blast and Wash demonstration facility. To arrange your free component testing, contact Guyson’s team today.