- Manual Blast Machines

- Euroblast 2 - Manual Blast Machine

- Euroblast 4 - Manual Blast Machine

- Euroblast 6 - Manual Blast Machine

- Euroblast 7 - Manual Blast Machine

- Euroblast 8 - Manual Blast Machine

- Euroblast 9 - Manual Blast Machine

- Euroblast 10 - Manual Blast Machine

- Euroblast Plus - Manual Blast Machine

- Euroblast Specials - Manual Blast Machines

- Automated Blast Machines

- Automated Ultrasonic Cleaning Systems

- Ultrasonic Baths and Tanks

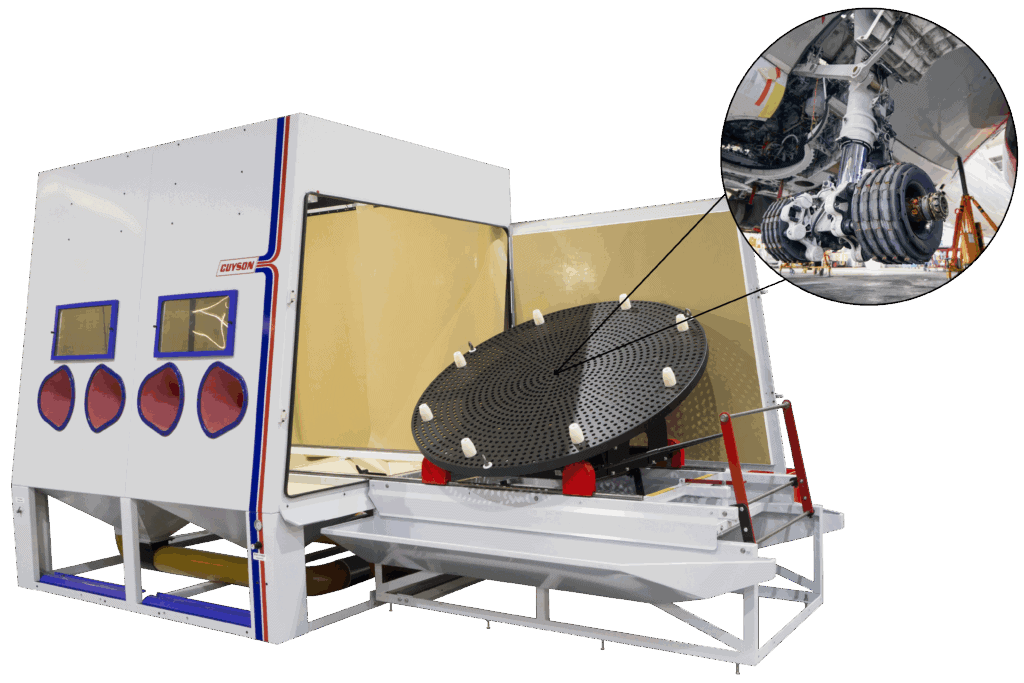

Aerospace

Guyson manufacture premium blast and ultrasonic cleaning systems for diverse finishing applications, within the aerospace aviation Industry.

Home > Industries & Finishing Applications > Industries > Aerospace

Aerospace OEM and MRO

Driven by advanced design, precision engineering, and state-of-the-art manufacturing, Guyson’s industry-leading surface finishing solutions are the go-to choice for numerous finishing applications, across the aerospace aviation industry.

Aerospace Solutions

Guyson have an extensive portfolio of manual and automated, blasting and ultrasonic cleaning solutions, renowned throughout the aviation industry.

Guyson proudly remains the trusted partner, who prioritises safety, quality and meticulous attention to detail, for many leading aviation Original Equipment Manufacturers (OEM) and Maintenance, Repair and Overhaul (MRO) companies, worldwide.

Blast In Action

- Euroblast 2 Metre Square Side Loading PF blast system, using grit blast media, removes oxide and coating layers during MRO

- Euroblast 2.5M Side Loading PF blast system etches large, circular aluminium rings, prior to bonding

- EB1 Tumbleblast machine uniformly treats the surface of aero blades

- Multiblast RSB utilised for shot peening and applying a cosmetic finish to turbine blades

- Multiblast RXS 900, using glass bead blast media, reconditions turbine compressor blades

- RB10 PF blast system shot peened turbine blade roots to AMS2432 standard

Ultrasonic Cleaning In Focus

- GUK Ultrasonic Baths utilised for ultrasonic cleaning fluorescent penetrant from Tam panel test pieces used in NDT operations

- Microclean 450 aqueous cleaning system used for removing cutting fluids from aerospace propeller casing components

- Microsolve Mono-Solvent systems provide meticulous cleaning results with avionics

- Microsolve Co-Solvent systems precision cleaned aircraft guidance systems and reconditioned gearbox components, hydraulic systems and actuators

Finishing Equipment FAQs

Suction feed vs pressure feed blast cabinet?

A suction feed blast cabinet uses a venturi siphoning action to draw the blast media from the cabinet hopper into the compressed air stream within the gun nozzle itself. The air and media pass through the nozzle, to be directed at the component.

A pressure feed cabinet stores the blast media within an external pressure pot. When the pot is sealed, the blast media falls through a valve into a compressed air stream within the blast hose. It is then accelerated through the blast nozzle to impact upon the component.

The pressure feed system produces faster moving blast media and offers cycle times that can be up to 4 times faster than a suction feed system.

Both methods can use a very wide selection of blast media. By additionally varying the media particle size and the blast pressure used, these two systems can offer a range of finishing from light, delicate work to high production, demanding and aggressive applications.

Our Manual Blast Equipment Guidelines brochure covers this and many other topics. Download the Blast Equipment Guidelines brochure here, or call 01756 799911 and ask Customer Service for further advice.

How does ultrasonic cleaning work?

Ultrasonic cleaning is brought about by the introduction of high-frequency sound waves (usually between 20-80 kHz) into a liquid by transducers, normally attached to the bottom of the tank. The resulting action is called ‘cavitation’. Cavitation is created by high and low pressure areas produced in the solution as the sound waves pass through it. In low-pressure areas, microscopic ‘bubbles’ form, then the pressure rises rapidly as the next sound wave passes through the solution. The millions of tiny bubbles violently implode and create a highly effective ‘scrubbing’ action on any immersed component surface. At the standard 38 kHz, this is happening 38,000 times per second.

What is shot peening?

Controlled shot peening is regularly being specified by the aerospace, automotive and nuclear industries to enhance component service life. It is a cold working process in which the surface of the component being processed is bombarded with small spherical media. Each piece of shot striking the surface of the component acts as a minuscule peening hammer, deforming the component surface and causing a small indentation or dimple. The overlapping dimples develop a thin layer of metal in residual compressive stress at or near the surface. Since nearly all fatigue and stress corrosion failures start at the surface of a part, the compressive stresses induced by shot peening can considerably increase component service life.

Our Shot Peening brochure covers this in more detail. Download the Guyson Shot Peening brochure here, or call 01756 799911 and ask our Customer Service department to send you a copy. Further information on Guyson shot peening equipment can be found here.

Post-Processing Additive Manufactured Parts - do Guyson offer a special blast cabinet for this?

Yes, the Guyson Euroblast Ex Range of ATEX blast systems have been certified for use in potentially explosive atmospheres, (such as those found in post-processing of additive manufactured components) where the use of fine powders of materials such as Plastic, Aluminium, Titanium and Inconel, can create potentially explosive atmospheres.

Do Guyson have any automated post-processing systems for Additive Manufacturing?

Yes, Guyson have become the first manufacturer to create an automated post processing system specifically for EBM (Electron Beam Melting) additive builds.

The Guyson Powder Recovery System (PRS) blast system comprises the blast chamber, with build box integration and containing a roof mounted 6 axis robot, as well as a high efficiency cyclone powder separator and dust collection system.

Replacing the arduous and difficult to control manual cleaning and blasting operations with an automatic, fast, repeatable and safe system the Guyson PRS ensures your printers enjoy as much up time as possible.

I’ve got a Guyson manual blaster but it’s too small for my current work. Do you make bigger or different machines?

Yes – the Guyson range of manual blast cleaning and finishing equipment is very comprehensive, with over 20 different blast cabinets available. These range from small bench top models to the large 2 metre square freestanding unit.

Call Customer Service on 01756 799911 for further information.

I’ve got a Guyson manual blast machine - do you make automatic machines as well?

Yes – Guyson can offer a wide range of automatic and semi-automatic blast machines for both blast and wash applications. Machine types will vary depending upon required throughputs, handling systems etc.

Our Component Finishing Centre at Skipton can be used to undertake a free of charge evaluation of your requirements before proposals for automation are made.

Please call Customer Service on 01756 799911 for more details.

How do I choose between ultrasonic cleaning and spray wash?

Aqueous spray washers are excellent for a wide variety of cleaning applications. Both stand-alone basket washers and conveyorised multi-stage equipment (incorporating rinse and dry sections if required) can often achieve rapid throughput plus high standards of cleanliness. In certain cases, heavy soils are better dealt with by spray washing, due to the impact of the pumped cleaning solution through the wash jets.

In other instances, spray washing and ultrasonic cleaning may both achieve the required cleanliness standard and throughput requirements, so the choice may be one of cost or preference.

However, there are applications where ultrasonic cleaning equipment offers a clear advantage over spray washing. Examples include the following:

- Components with deep, blind holes or complex geometries

- Tubular components

- Delicate or lightweight components that could be susceptible to damage

- Achieving sub micron cleanliness standards or cleanliness levels measured in parts per billion (ppb)

To help you find out which process may be most suited to your application, we offer a free of charge evaluation service. Our Component Finishing Centre at Skipton have a wide selection of both spray wash and ultrasonic cleaning machines and we can perform cleaning trials on your own components to establish the optimum process.

Do you still supply Kerry plastic welding assembly equipment?

No – when Kerry Ultrasonics was acquired by Guyson International Ltd, the plastic welding assembly division was transferred to Sonics & Materials UK Ltd. Enquiries about plastics assembly equipment should be directed to Sonics & Materials UK Ltd, http://www.sonicsandmaterials…. tel 01858 434059

Has Guyson any ultrasonic test facilities that I can use to prove the cleaning process on my parts?

Yes, Guyson has a specially built Precision Cleaning Facility (PCF) within its demonstration and showroom area at Skipton.

Component cleaning trials, demonstrations and precision cleaning development work are undertaken in a controlled environment, which is particularly helpful to customers such as medical implant, aerospace and electronic PCB manufacturers who must achieve validation for their cleaning processes.

Analytical equipment is also provided for cleanliness testing.

Call Customer Services on 01756 799911 for more information.

I have an old 'Kerry Ultrasonic' cleaning system. Can Guyson service it for me?

Most probably, yes. Guyson’s Kerry ultrasonic customers in England, Scotland and Wales continue to be supported by experienced local service engineers. Elsewhere in the world service is normally provided by our network of distributors, or by Guyson subsidiaries near Paris, France; Saratoga Springs, New York State, USA; Penang, Malaysia; and Wuxi, China.

For a speedy answer, please email Guyson, including if possible the serial number of your machine as well as its name/description.

We would like to switch to cleaning with solvents but won't it be expensive?

Solvent retention features which help make Microsolve systems SED-compliant (ie safe for operators and environmentally acceptable) also mean that little solvent is lost to the atmosphere or carried out on components, making the equipment extremely cost-effective in use.

Our Microsolve systems can be fitted with a solvent top-up and monitoring device which allows users to check consumption: 3 litres of HFE (hydrofluoroether) per 40-hour week is typical usage for a Co-solvent 350 system.

Guyson Autotrans i-Drive automated basket handing systems also reduces daily running costs by controlling the speed of basket entry and withdrawal from the vapour zone, thus reducing solvent drag-out and losses to atmosphere caused by disturbance of the vapour blanket. Additionally assuring consistent, repeatable quality, reducing reject rates, and increasing throughput.

Can you recommend a suitable detergent for my wash machine?

For general degreasing applications, Guyson Formula 10Plus is available in 25 litre containers. This concentrated product can be used in all Guyson spray washing machines to give high performance degreasing combined with corrosion protection on all metals.

The performance of my parts washer doesn’t seem to be as good as it was when it was new. What could have changed?

There are a number of factors that will have changed since the equipment was first used.

For instance, filters and wash jets may become blocked as debris is removed from the components being washed. Detergent concentrations may have varied and greases or oils could have built up at certain points in the machine, again restricting flows. Similarly, the performance of the wash pump may have deteriorated over time. Also, if the machine has more than one heating element, one may have failed giving a reduced wash temperature. Any of these problems, either singly or combined, may now be contributing to a general drop in performance.

Look through the manual for further details regarding your specific machine and then check each area in turn. If you need further assistance, please call our Service Department on 01756 799911 to talk about arranging a service visit or contract.

We need a solvent cleaning system - how can I be sure we don't fall foul of the Solvent Emissions Directive?

Guyson ‘Kerry’ Microsolve precision cleaners are designed to use new, low-toxicity solvents with zero OPD (Ozone Depletion Potential). Plus, both our Microsolve ranges, Co-solvent and Mono-solvent, have extremely effective solvent retention features. These systems, correctly used with hydrofluoroethers (3M™ NovecTM HFE) or hydrofluorocarbons (HFCs), are fully compliant with the SED.

Can you help me identify spare parts for my Guyson machine?

We retain records of all machines produced over the past 25 years and can probably help you even if your equipment is older. Spare parts lists covering all the common parts on both blast and wash machines are available from Customer Service on 01756 799911.

Blast and wash users can now also download from our ‘Spare Parts’ section the blast systems parts list and photograph guides to help identify the parts required.

Before you call, make a note of the serial number of your machine. This will help our team advise you more easily.

How much compressed air do I need to run my blast machine?

To answer this, we will need to know the type of blast system you have – i.e. is it suction feed or pressure feed? Once this is known, the air consumption will further depend upon the bore of the air control jet (suction feed) or the bore of the nozzle (pressure feed) and also the blast pressure you are using.

Please call our Customer Service team for advice and assistance.

How to choose a blast cabinet

For all you need to know about the systems, the options, the sizes – and how to choose the best machine for you, download the ‘Guyson Manual Blast Equipment Guidelines’ for further background information on blast equipment selection.